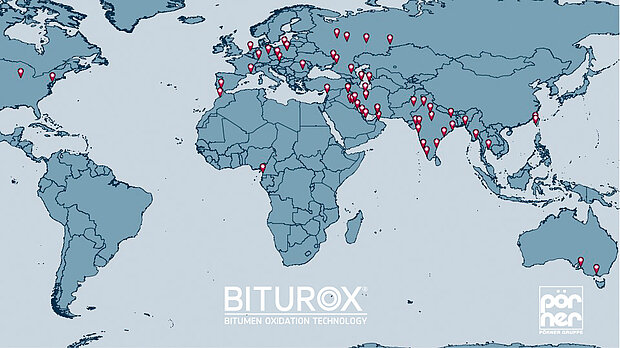

Global Market Leader in Bitumen Production

Pörner Biturox® Bitumen

For over 45 years, the Pörner Group has specialized in bitumen technologies. With over 60 licensed Biturox® bitumen plants, the group is the global market leader in bitumen oxidation technology. Together, these plants account for around 12% of the world’s bitumen production capacity.

The Biturox® technology ensures superior bitumen quality, produced from a wide range of cost-efficient refinery feedstock. This enables bitumen production from a broader spectrum of - sometimes even challenging - raw materials.

Everything from a Single Source

Our engineers design and realize turnkey bitumen plants, including exhaust gas treatment and all necessary auxiliary units, from a single source. The result: fully automated, environmentally friendly process plants built according to modern refinery standards, with a long service life.

We offer consulting, process design, application engineering, and the construction of complete bitumen production plants using the oxidation process.

In our in-house research laboratory, we develop customized Biturox® concepts that meet international product standards using available crude oils and refinery intermediates.

Technology Overview

The Biturox® process provides users maximum flexibility in processing various crude oils while ensuring superior bitumen properties through environmentally friendly and cost-efficient production.

"Biturox stands for better quality from more economical feedstock."

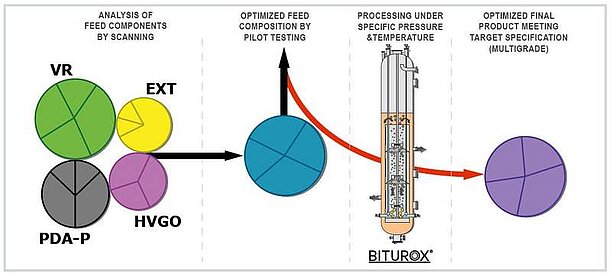

The following refinery feedstock and intermediates can be used as input components:

- Vacuum Residues (Short Residue, VR)

- Solvent deasphalting residue (SDA)

- Vacuum gas oil (VGO), and heavy vacuum gas oil (HVGO)

- Aromatic extracts from lube oil aromatics extraction (EXT)

- Other raw material components

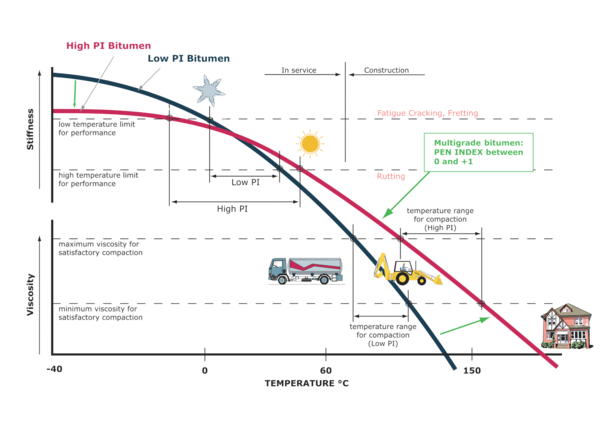

Multigrade bitumen

The Biturox® process is used worldwide for the highly economical production of bitumen in accordance with international standards, as well as for the production of specialty bitumen (multigrades), industrial bitumen, and polymer-modified bitumen (PMB).

Compliance with various national regulations is always ensured:

- Penetration grades (e.g., European and most national standards)

- Performance grades (e.g., U.S. SHRP standards)

- Viscosity grades (e.g., Australian and Indian standards)

Biturox® plants produce large volumes of high-quality bitumen at the lowest CAPEX and OPEX costs.

Key benefits for producers include:

- High-quality bitumen can be efficiently produced through downstream chemical processing from a wider range of crude oils and refinery feedstock. When only light-to-medium crude oil is available, the Biturox® process is often the only viable option for producing quality bitumen.

- The properties of the final product are precisely controlled throughout the process.

- Continuous operation ensures consistent quality and high production capacity.

- Adjustments to bitumen properties (grades) can be made without interrupting operations.

- The process is fully automated and integrated into a modern refinery for safe operation.

- Compared to straight-run bitumen, Biturox® bitumen has a flatter viscosity curve and a higher PEN index. This makes it more resistant to highly variable climatic conditions.

- Its high resistance to rutting, excellent fatigue durability and outstanding aging stability ensure a longer service life for road pavements.

- Complete implementation of all required infrastructure (tank farms, truck and rail loading stations) from a single source.

More than 40 Biturox® plants have been built worldwide.

Benefit from Pörner’s over four decades of experience in bitumen plant engineering.

Pörner supplies modern bitumen plants of all sizes, from specialty units to large-scale plants with production capacities of up to one million tons per year, all from a single source:

- with proven process engineering solutions down to the smallest detail,

- equipped with the best components available on the global market, and

- leveraging locally available cost-efficient resources.

This approach ensures the fast, cost-effective realization of optimal, highly automated, low-maintenance, environmentally friendly plants that are seamlessly integrated into modern refineries.

Scope of work:

- Consulting, pre-project studies, feasibility studies

- Feedstock evaluation, pilot plant product manufacturing, analysis

- Project management

- Process development, licensing & basic engineering

- Detail engineering (equipment, machinery, piping, steel structures, electrical & instrumentation, automation, civil works), authority engineering

- Procurement of equipment and materials, logistics

- Contracting of construction and installation companies, construction supervision

- Personnel training, plant commissioning

- Acceptance tests

- Documentation

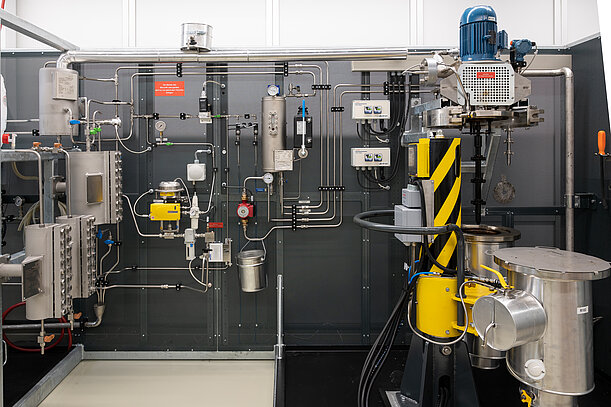

In our in-house research laboratory, we develop custom Biturox® solutions that meet international product standards using available crude oils and refinery intermediates.

Our newly developed Biturox® Pilot Plant 2.0 is equipped with a process control system that regulates process air, reactor pressure, and process water. With two reactors of 7.5 and 15 liters capacity, it offers greater flexibility.

The main objective of Biturox® research is to optimize the product quality by identifying the ideal feedstock blend and defining the process parameters in the Biturox® reactor. At the beginning of a project, Pörner conducts test programs in the pilot plant to maximize the quality of the given raw materials (e.g., PEN index between -1 and +1, aging resistance, etc.).

We store all results from fundamental and applied research, experience gained during Biturox® plant development, construction, and commissioning, feedback from Biturox® licensees, the latest Biturox® upgrading process findings (chemical bitumen upgrading), and performance reports from Biturox® bitumen use in a comprehensive database.

Based on this data, Pörner determines the most efficient and cost-effective method for producing high-quality bitumen tailored to your needs.

Technology-Flyer

Albert Traxler

Sales Manager CIS Countries / Asia

Phone: +43 5 05899-0

Email: albert.traxler@poerner.at