MORE THAN JUST SEPARATION: EFFICIENT PROCESS FOR PREMIUM PRODUCTS

Dewaxing

The DEWAXING technology is an innovative process for the production of high-quality lubricating oils, using solvents and incorporating scraped surface chillers and vacuum drum filters.

The demand for high-performance lubricants that reliably function under extreme conditions is continuously increasing—primarily driven by industrial needs outside the transportation sector.

In response to growing sustainability requirements, modern dewaxing units increasingly rely on energy-efficient process operation and targeted emission reduction.

With the DEWAXING technology, we offer an efficient solution for producing high-quality base oils. The objective is the targeted removal of long-chain paraffins, which tend to crystallize at low temperatures and thereby negatively affect flow properties and viscosity. In addition, slack wax is produced, which is used in wax manufacturing.

Technology Overview

Feedstocks include base oils and deasphalted oil (bright stock) from the SDA unit for lubricating processing.

Products of the DEWAXING process are dewaxed base oils with defined pour points for industrial lubricant applications, as well as slack wax for wax production.

Waxes are obtained from vacuum distillate fractions or deasphalted oil (DAO) via solvent deasphalting of vacuum residue. Using the classical solvent crystallization method with MEK/toluene, a high-quality wax with an oil content below one percent can be produced from slack wax, which can also be upgraded to food-grade quality through wax hydrotreating.

By combining both processes (with and without solvents, two independent process stages), significant advantages are achieved over traditional solvent-based technologies:

- Processing of medium to heavy feedstocks

- Higher yield of hard waxes from light to medium feedstocks

- Significant savings in capital and operating costs

- Energy savings through improved thermal integration of the plant

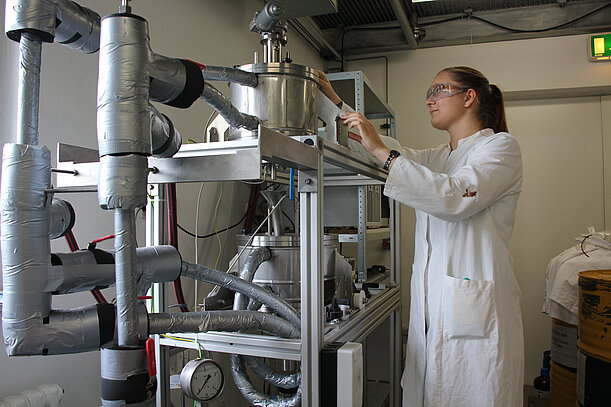

Design reliability with in-house test facility

At our dedicated test facilities in Leipzig, located at the Institute for Non-Classical Chemistry (INC) at Leipzig University, and in collaboration with our partner, we conduct investigations to determine equilibrium data, product yields and qualities, design parameters, as well as tests with various solvents such as MEK/toluene mixtures and others. In addition, we optimize the solvent-to-feedstock ratio and the solvent composition.

Based on the laboratory data, the plant is designed using proprietary process simulation software developed by EDL, incorporating its own specialized calculation models.

Technology Flyer

English