EFFICIENT AND ENVIRONMENTALLY FRIENDLY PRODUCTION OF PROCESS OILS

Solvent Extraction

Solvent extraction is an innovative process using agitated columns and the solvents furfural and NMP, including co-solvents.

Our solvent extraction is an effective environmentally friendly technology for producing high-quality products in lube oil refineries and for petrochemical applications. By extracting vacuum distillates and deasphalted oil (DAO) with suitable solvents, high-grade lubricating oils and special plasticizer oils (TDAE/TRAE, MES, etc.) are produced. Furthermore, compared to the hydrogenation process, solvent extraction is an attractive and cost-efficient alternative to produce white spirit.

Technology Overview

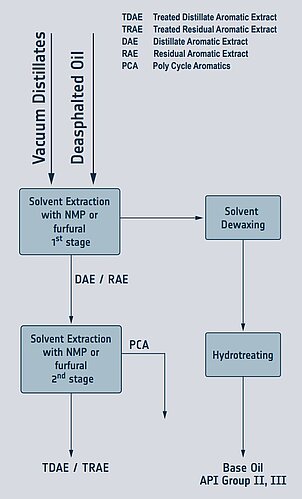

Feedstocks include vacuum distillates (lube cuts) and deasphalted oils from the SDA unit.

Products of the EXTRACTION process are base oils with reduced aromatics content for lubricant production as well as process and extender oils for tire manufacturing, such as highly aromatic extracts (DAE and RAE) and treated highly aromatic extracts (TDAE and TRAE) with reduced levels of polycyclic aromatics (PCA).

The central element of EDL’s technology for producing high-quality base and process oils from vacuum distillates (lube cuts) and deasphalted oils (DAO) is a two-stage extraction process.

First extraction step

In the initial extraction step, aromatics are separated as so-called DAE (Distillate Aromatic Extract) or RAE (Residual Aromatic Extract). NMP (or furfural) is used as solvent. The resulting oils having a very low aromatics content are used to produce high-quality base oils.

Second extraction step

In a second extraction step, DAE and RAE are processed using a proprietary solvent blend to produce high-quality process oils such as Treated Distillate Aromatic Extract(TDAE) and Treated Residual Aromatic extract (TTRAE) with a low content of polycyclic aromatics (PCA).

When implementing the technology into a plant optimized according to client’s requirements, we collaborate with various renowned manufacturers of extraction columns (rotating or static). They convert our technological process specifications into state-of-the-art internals.

Key benefits of our EXTRACTION technology for the client include:

- High flexibility in feedstock selection due to the option of single- or two-stage extraction for improved product quality

- Optimized solvent selection

- Excellent heat integration

- Significant reduction of polycyclic aromatic hydrocarbon (PCA) content in TDAE and TRAE, well below the 3wt% limit set by EU Directive 2005/69/EC

- Up to 50 percent higher capacity at consistent product quality through the use of agitated column internals

- Cost-effective alternative to produce white spirit compared to a hydrogenation process

Design reliability with in-house test facility

At the Institute of Non-Classical Chemistry (INC) at Leipzig University, our clients have access to our modern pilot plant for comprehensive solvent extraction testing, as well as at our cooperation partner’s site. This enables the determination of liquid-liquid equilibrium data, design parameters, and product qualities. Various solvents – such as NMP, furfural, and special solvent blends with co-solvents – are examined and compared.

The results of these tests, combined with proprietary software for plant design, form the basis for offering our clients the optimum solution tailored to their specific quality requirements.