Cold Bitumen Logistics

Bitumen Packing System

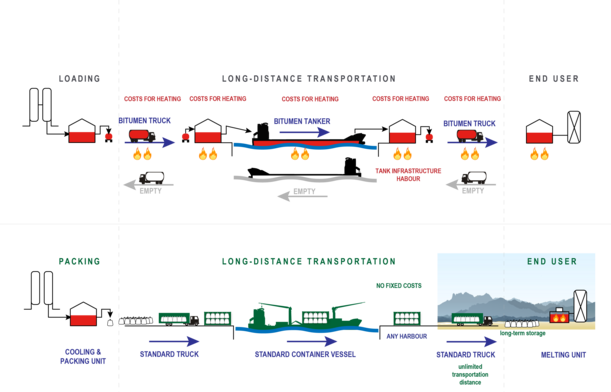

The Pörner Bitumen Packing System (PBPS) consists of a complete solution that is designed to pack road-paving bitumen into the flexible containers (Pörner Bitumen Bag™) and transport it by any means of transportation.

The Pörner Bitumen Packing System (PBPS) is a comprehensive cold bitumen logistics/supply chain solution for the bitumen industry. It addresses all aspects of the bitumen producer, logistics, distributor and end-user.

The Pörner System

Cold Bitumen Logistics

The Pörner Bitumen Packing System (PBPS)'s core element is the Pörner Bitumen Bag™, a lightweight, durable and flexible bag optimized for container transport that provides a number of economic and logistical advantages for the entire supply chain. With its unparalleled features, PBPS can increase the producer margins, reduce transportation costs and reach markets previously not economically served.

The patented innovative Pörner Bitumen Bag™ has been developed by Pörner Group.

System Features

The Cooling & Packing Unit (CPU) cools the finished bitumen to packing temperature for a stable, safe and continuous operation. The bitumen is then filled into the Pörner Bitumen Bag™ under electronic control for accurate weighing and monitoring. Each bag is marked with a unique serial number and barcode to register the product and the individual weight of each bag.

The CPU is a compact, semi-automatic process unit that does not require much space, is ideally located near the bitumen production plant, and can be supplied by a pipeline or tankers.

The patented innovative Pörner Bitumen Bag™ is a self-stabilizing plastic container, consisting of a multi-layer outer bag (recyclable) and a special inner liner. The liner is fused together with the bitumen without altering its properties. The latest generation of bags includes a simple frame structure for extra stabilization to accommodate the larger mass.

The Pörner Bitumen Bag™ is designed to carry up to 1,300 kg of road paving bitumen and is available in a variety of sizes to meet the customers’ requirements. Its shape and volume is optimized for maximum utilization of containers and trucks.

The bag can be transported by any common transportation system (container, truck, rail) and is a one-way logistic solution. Therefore, the transporter can be used for other cargo on its return. The bag has UV light protection and is suitable for any climate zone. It can be stored for up to 12 months (storage limitations apply according to storage instructions).

At the end of the supply chain, the Pörner High-Performance Melting Unit (HPM), which is the central element of a Melting Terminal, re-liquefies the bitumen for the final application.

The Melting Terminals replace depots and bitumen terminals and are a cost-effective alternative to expensive conventional infrastructure with a small one-time investment. Instead of heated tanks or inefficient drum decanters, the Melting Terminal requires only a flat, compacted storage area and at least one HPM.

The HPM is probably the most efficient bitumen melting unit and has been designed by our Pörner process engineers. Its central component is a melting grid with high-tech heat distribution and heat recovery. It needs only one person for operation and requires any form of available energy, e.g. diesel, paraffin or gas. Consumption is as low as four liters of diesel (or energy equivalent) per ton of bitumen melted, depending on ambient temperature.

Advantages:

- Expand your bitumen sales market

- Melt and supply just-in-time on demand

- Balancing seasonal fluctuations

- Use conventional means of transportations (i.e. containers, standard container/flatbed trucks, rail cargo etc.)

- Substantial energy saving – no heating required during transport and storage

- Long-time storage up to 12 months without energy requirement

- Significant cost savings over the entire supply chain compared to conventional bulk transport, bitutainers or drums

- Reduce environmental foot-print

- Reliable and efficient equipment (CPU and high-performance melters)

- More independence and flexibility for your supply chain

The quintessence of the Pörner Bitumen Packing System is the one-way transport of bitumen in cold condition in an environmentally friendly, flexible, lightweight and economic container. In addition, PBPS allows bitumen to be stored at virtually no cost. Huge investments in terminals and storage infrastructure become obsolete.

- Small one-time investment

- Low equipment maintenance requirements

- Low manpower requirement

- Quickly setting up a depot in other locations when needed (e.g. near a large project construction site)

- Relieve the end user of bitumen logistics

- Melt and deliver on demand and just in time

Technology Brochure (EN)